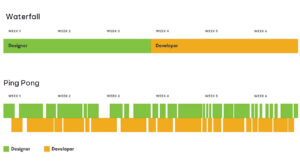

The Ping-Pong Strategy in UX Design

Imagine stepping into the world of UX design where collaboration isn’t just encouraged; it’s the essence of creativity. This is the heart of the Ping-Pong Strategy, a dynamic, iterative process that mimics the swift, back-and-forth action of a ping-pong game. Just as a game requires agility, focus, and seamless cooperation